My very best wishes to you, and that it becomes everything that you wish it to be.

Good luck.

Homogenization is the real deal and thanks so much to @anon96069639 for the brilliant idea and execution.

@SmilingOgre did a great video on mixing with a homogenizer but searched and searched here and haven’t found it yet.

Maybe we start a new thread on how people are using it or should we post it here?

Oh sure, the evil clown taunts me again…and you wonder why you give me nightmares ![]()

Absolutely! Even with the original beta unit I received, the reality of the ability to achieve a homogenous mix was proven beyond a shadow of a doubt!

I couldn’t agree more!

His choice of using a commonly available, and reasonably priced device (high-speed, hand-held rotary tools) to power his creation was brilliant!

And this is going to be a game changer for those fortunate enough to get one and take the time to use it as designed/intended!

I wouldn’t go that far… lol

Even the USC method (with properly applied heat levels) beats the “put it in a dark cubby and forget it” method. Because even then (again, with proper methodology, and durations

[depending on the flavors one’s working with]), time waiting can still be reduced by 60-75%.

Unfortunately, some folks just refuse to adjust their mindset, as well as do empirical testing on their own to learn something that goes against the commonly repeated rhetoric by some…

Regardless, even as nice as using a USC has been in my experience, the homogenizer designed by @anon96069639 is another HUGE step forward in the process, and easily leaves the USC method in it’s wake. There’s just NO competition for the results of using a Homogenizer!

I consider myself fortunate to have been able to help test things out, and witness the excellence in design firsthand.

Thank you again Dan for allowing me to be a part of this! I’m extremely grateful bud.

The one I made and posted on ELR was full of jabs at the naysayers of homogenizing and some political jabs as well. I think it would be better to make a new one that was more serious and used the GT homogenizer. I’ll go ahead with that here shortly.

All I can say is I’m totally blown away, I have zero knowledge or experience using Homogenizers (I have a 1 gallon paint shaker jerry rigged up for bottles down to 10ml) but from what I see here this is amazing, possibly ground breaking for DIY mixing. ![]()

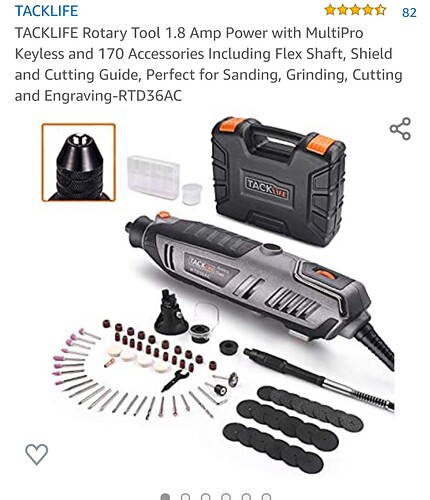

Omg i forgot to check which dremels I owned

Will either of these types work ??? If not I have no problem buying the proper tool , but these are nice and small and can pick them up anywhere…

I had to dig for those bc i rarely use them anymore, havent used dremels in years

Actually i like the vlack and Decker one you shiwed me ill pick that one up…The RTX looks smaller and looks like it is more comfortable in the hand

Your right they have been used for construction , flooring etc …I dodnt even think about the dust , i meant the type… I’m going to grab a RTX and ill get with you ASAP …

Interesting watching the heated VG vs non heated VG. The same is true when working with a magnetic mixer, one really needs to heat the VG to get the VG to move.

Here are my thoughts and observations using the high shear homogenizer.

Although it was designed for smaller amounts, I have used it to mix 500 ml batches and it works flawlessly.

It’s well designed, durable, and is easy to disassemble to clean.

It mixes, blends and otherwise infuses all components of the eliquid into one another to become a single entity almost instantly, all without introducing air. It really makes stirring and other mechanical mixers seem like toys.

I have used heat to thin my VG for years, ignoring those proclaiming detrimental effects. I saw no difference in taste or quality of my eliquids other than it was easier to mix and cut down on the maturing process. Of course I always added the nicotine last.

My favorite eliquids usually take about a week to fully mature with conventional mixing methods such as a mechanical stirrer or magnetic mixer. Using the homogenizer, they are done instantly. There is no waiting or checking. It’s done. Period.

Aside from the saved time waiting for maturation, the liquids are mixed on a different level. All the flavors are fully combined with each other and come together more as a single flavor. Something that I have never experienced from conventional mixing methods. Its made my favorite juices taste like how I always imagined that they would taste.

I think the homgenizer that @anon96069639 designed is a huge leap forward for the DIY mixing world. Its better, faster and eliminates “steeping” or the maturing process. It blends the flavors more completely. I hope I never get caught in a situation where I have to go back to a mag mixer or other conventional mixers.

I agree, when I use my magnetic heated stirrer, I add nicotine after it has cooled.

Is that stand necassary ??? Where did you get it

OMG …Thats a stand for a drill press ??? I might have one somewhere in storage

The stand is not necessary, it does make it easier to adjust your speed while the dremel is on.

I like that, hmmmm, a new company, “The Jaggenheimer Group” full on Ponzi scheme but I have always wanted to live in a no extradition country anyway ![]()